From LED Chips to Complete Headlights: The Production Process Revealed —— BLIAUTO Professional Analysis

Bliauto reveals the full production process—from LED chips to complete headlights. Professional analysis for brand manufacturers of LED headlights, manufacturing LED headlights, and wholesale LED headlights, covering quality control, assembly, and supply solutions.

- I. Raw Material Preparation: Quality Control from the Source

- 1. LED Chips

- 2. PCB Substrate

- 3. Optical Lens and Reflector

- 4. Housing and Heat Sink

- 5. Driver (Power Supply)

- II. LED Packaging: The Core of Efficiency and Stability

- 1. Packaging Process

- 2. Key Factors in Packaging

- 3. Quality Verification

- III. Thermal Management: The Key to Lifespan

- IV. Optical Design: Beyond Brightness, Towards Safety

- 1. Beam Pattern Design

- 2. Optical Simulation

- 3. Road Testing

- V. Headlight Assembly: Precision Manufacturing

- VI. Rigorous Testing and Verification

- VIII. Future Trends: Toward Intelligence and Personalization

- Conclusion

In the automotive lighting industry, LED headlights have gradually replaced halogen and HID lamps, becoming both the standard configuration of modern vehicles and a top choice for aftermarket upgrades. They not only represent a leap in lighting technology but also embody a balance of safety, design, and performance.

So, how does a high-quality LED headlight evolve from tiny LED chips to a fully assembled unit ready to be installed on a car? This article will take you inside the production process of LED headlight manufacturers, uncovering the craftsmanship, technologies, and standards behind it.

I. Raw Material Preparation: Quality Control from the Source

The quality of LED headlights depends 80% on the choice of raw materials.

1. LED Chips

Main suppliers: CREE, OSRAM, Lumileds, Nichia, etc.

Key factors: brightness, lifespan, color rendering index (CRI), and luminous efficiency.

Premium chips can last 30,000–50,000 hours.

2. PCB Substrate

Common materials: copper substrate, aluminum substrate.

Function: provides current conduction and thermal dissipation for LED chips.

High-end lamps often use copper substrates, which have better thermal conductivity than aluminum.

3. Optical Lens and Reflector

Lens: PC/PMMA material, UV-resistant and high-temperature resistant.

Reflector: aluminum alloy with vacuum coating, determines light distribution pattern.

4. Housing and Heat Sink

Materials: die-cast aluminum alloy, aviation-grade aluminum, or advanced graphene cooling plates.

Requirements: heat resistance, corrosion resistance, and vibration resistance.

5. Driver (Power Supply)

Functions: voltage conversion, constant current output, interference suppression.

Premium drivers must include overcurrent protection, overheat protection, and EMI resistance.

Summary: Every step in material selection directly impacts the lifespan, safety, and performance of the final product.

II. LED Packaging: The Core of Efficiency and Stability

After being manufactured, LED chips must undergo packaging before being applied in headlamps.

1. Packaging Process

Chip mounting → wire bonding → phosphor coating → encapsulation → curing.

2. Key Factors in Packaging

Phosphor ratio: determines color temperature (common ranges: 3000K, 4300K, 6000K).

Silicone transparency affects luminous efficiency and degradation resistance.

Welding quality: poor soldering leads to early failures.

3. Quality Verification

Luminous flux testing (lm).

Color temperature consistency testing.

Thermal resistance testing (ensures low thermal resistance for better heat dissipation).

III. Thermal Management: The Key to Lifespan

LED chips are sensitive to heat—once junction temperature exceeds 150°C, lifespan drops significantly.

Common Cooling Methods

Fan Cooling: active cooling, highly efficient, but prone to dust accumulation and noise.

Copper Braided Heat Straps: flexible installation, fast heat transfer, suitable for tight spaces.

Liquid Cooling: an advanced solution, mainly for racing or specialized vehicles.

Graphene Thermal Conduction: an emerging material trend that is lightweight and efficient.

BLIAUTO Tip:

High-quality thermal designs allow LED headlights to operate reliably from -40°C to +125°C.

IV. Optical Design: Beyond Brightness, Towards Safety

A good LED headlight is not just about being “bright” but also about being “controlled.”

1. Beam Pattern Design

Low Beam: sharp cutoff line, prevents glare for oncoming drivers.

High Beam: concentrated light, illumination distance up to 150–200 meters.

2. Optical Simulation

Software: TracePro, LightTools.

Ensures beam patterns comply with ECE/DOT/SAE regulations.

3. Road Testing

Dark-road tests: evaluate illumination uniformity.

Fog/rain testing: assess penetration ability.

V. Headlight Assembly: Precision Manufacturing

Assembly Steps

Driver and LED module installation.

Housing and heat dissipation structure assembly.

Lens/reflector positioning.

Waterproof sealing with gaskets or potting compounds.

Final enclosure sealing and screw fastening.

Assembly Requirements

IP67/IP68 waterproof rating.

Vibration resistance according to automotive standards (50 Hz–2000 Hz).

Wiring harnesses use waterproof connectors, compatible with OEM sockets.

VI. Rigorous Testing and Verification

Common Tests

Optical Tests: luminous flux, beam pattern, light distribution.

Electrical Tests: voltage range, surge protection, EMC compliance.

Environmental Tests: thermal shock, humidity, salt spray.

Lifespan Tests: continuous operation for 5,000–10,000 hours.

Vehicle Validation: on-road testing, vibration testing.

Certification Standards

Europe: ECE R112, R128.

USA: DOT SAE.

China: GB 25991.

VII. FAQ (Frequently Asked Questions)

Q1: Why are some LED headlights bright but glaring for oncoming drivers?

A: Because of poor optical design and lack of a proper cutoff line. Quality manufacturers always design beam patterns according to regulations.

Q2: Which is better, fan cooling or fanless design?

A: Fan cooling dissipates heat faster but may suffer from dust and shorter fan life. Fanless designs are more durable but require more space. Choose based on your vehicle.

Q3: Why do cheap LED headlights fail quickly?

A: They may use inferior chips, poor-quality drivers, or lack proper heat dissipation, leading to rapid light decay or burnout.

Q4: What is the best color temperature for LED headlights?

A: 4300K–6000K is recommended, balancing penetration and comfort without excessive glare.

Q5: Do LED headlights require wiring modifications?

A: Most are plug-and-play, but some vehicles may need decoders or relays.

VIII. Future Trends: Toward Intelligence and Personalization

Matrix LED: automatically adjusts beams to avoid glare.

Laser-assisted LED: high beams with a range beyond 500 meters.

Custom Designs: integrated DRLs, sequential turn signals.

Vehicle-to-X Integration: Headlights linked with ADAS and autonomous driving systems.

Conclusion

From a tiny LED chip to a fully functional automotive headlight, the entire process involves dozens of sophisticated procedures and testing stages. Every detail safeguards performance and safety.

At BLIAUTO, as a professional LED headlight manufacturer and supplier, we adhere to high production standards and strict testing systems, delivering reliable, durable, and regulation-compliant lighting solutions worldwide.

Choosing high-quality LED headlights is not just an investment in driving safety but also an upgrade in vehicle performance and personalization.

Learn more about our automotive lighting products.

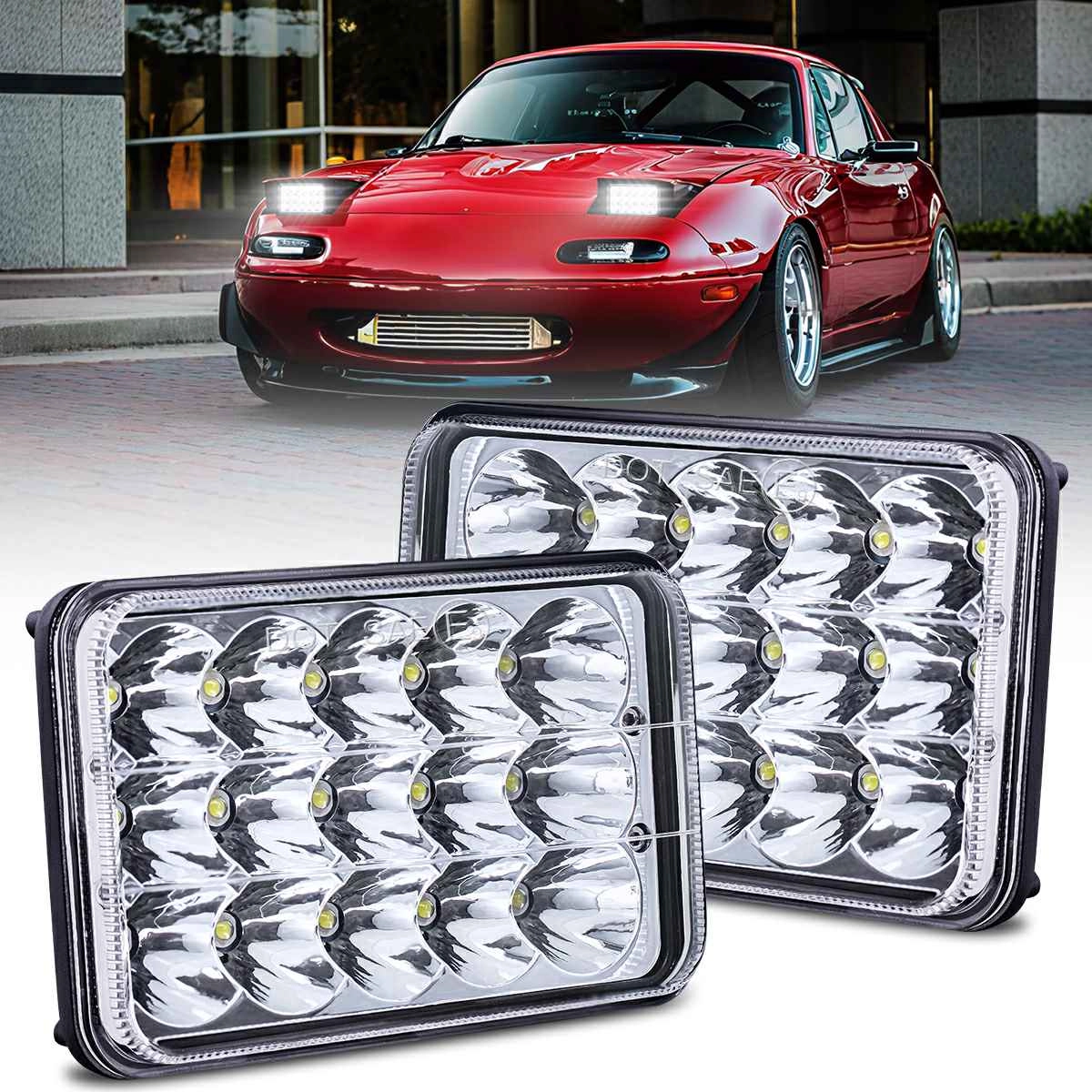

The most advanced line of high-performance LED headlights available. Model 2046 provides a 4×6 LED headlight with a high and low beam design as the main lighting for the vehicle.

Bliauto Motorcycle Headlight - Model C1H-WA: High-quality LED design from leading brand manufacturers of motorcycle headlights. Precision Manufacturing Motorcycle Headlight ensures high visibility, durability, and easy fit for all riders.

Bliauto JS1 Jump Starter – Reliable Power On-the-Go As a brand manufacturer & wholesale jump starter supplier, Bliauto delivers high-quality portable power solutions. The JS1 Jump Starter provides instant engine starts, USB charging, and durable performance—ideal for emergencies. Trusted by professionals, it’s compact, safe, and backed by expert engineering. Wholesale options are available—power up with Bliauto! Optimized for SEO with target keywords while maintaining clarity and brand authority. Let me know if you'd like refinements!

Bliauto Motorcycle Headlight - Model C1H-HL: High-quality brand motorcycle headlight with durable LEDs, easy installation, and high-beam performance. Trusted brand manufacturers motorcycle headlights for safety. Choose Manufacturing Motorcycle Headlight quality.

Connect with Bliauto for Automotive LED Lights Solution

Bliauto is dedicated to designing innovative automotive LED lighting systems. Let's talk about your needs!

© 2025 Bliauto All Rights Reserved.

Bliauto

Bliauto Light

Bliauto

Bliauto Light

Bliauto

Whatsapp: +8618811846160